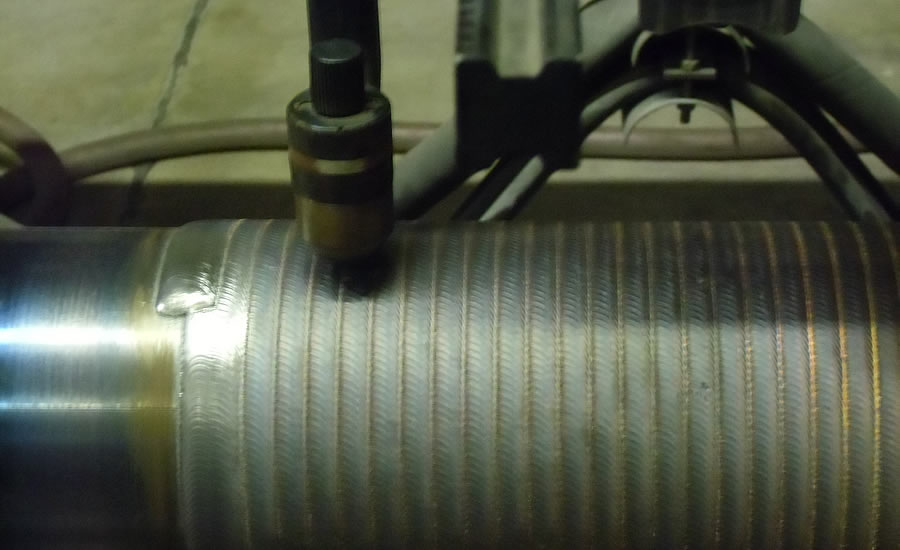

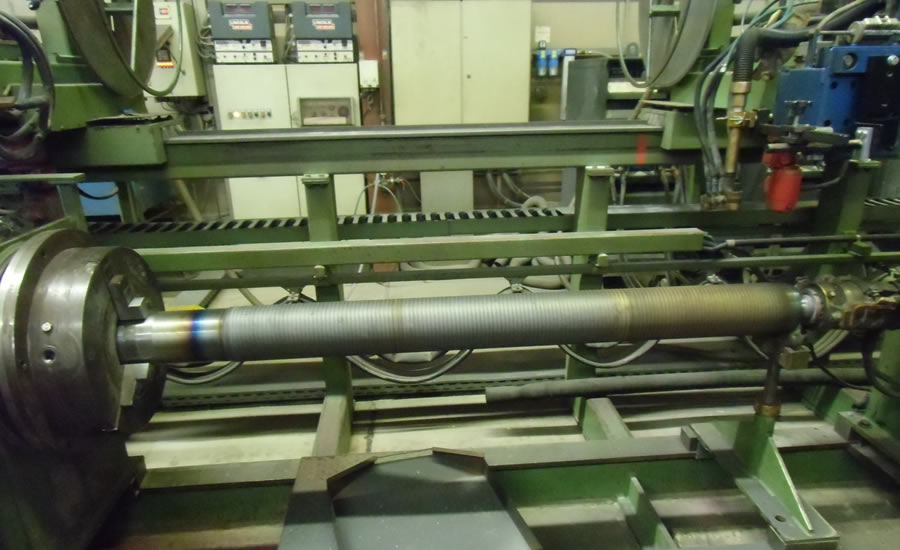

Plasma powder buildup welding

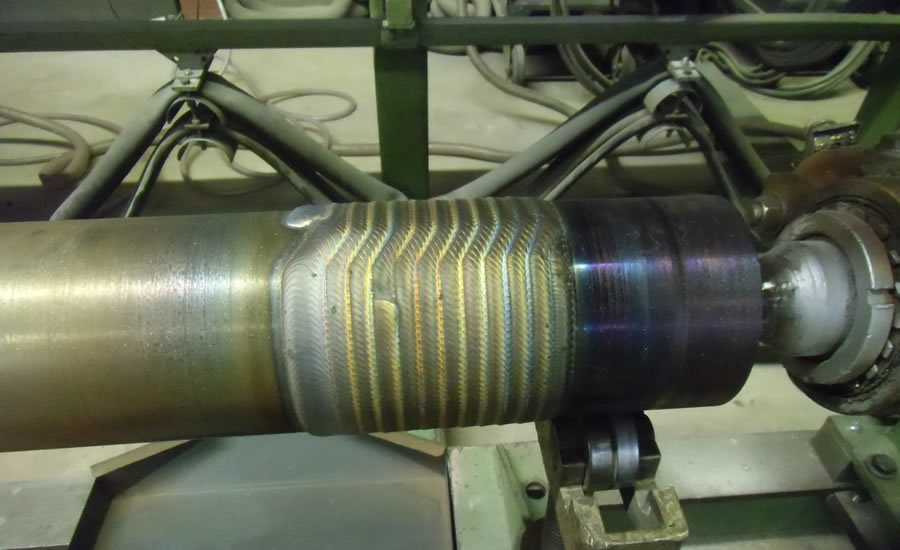

The plasma powder buildup welding (PTA “Plasma-Transferred-Arc”) is a hard facing thermal coating process in surface finishing, that enables to produce with the PTA process a high quality / or hard wearing surface from an base material.

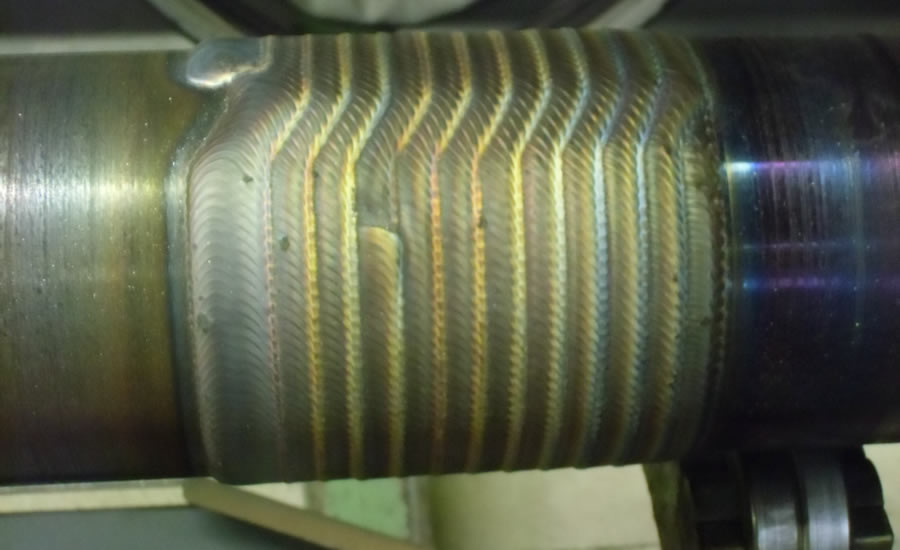

In this welding procedure thought build-up welding of wear and corrosion resistant coatings, a protective metallurgical surface is produced with the base material. (For example: low alloy steel, Stainless Steel, cast iron, bronze, nickel-base –super-alloys).

Working principle

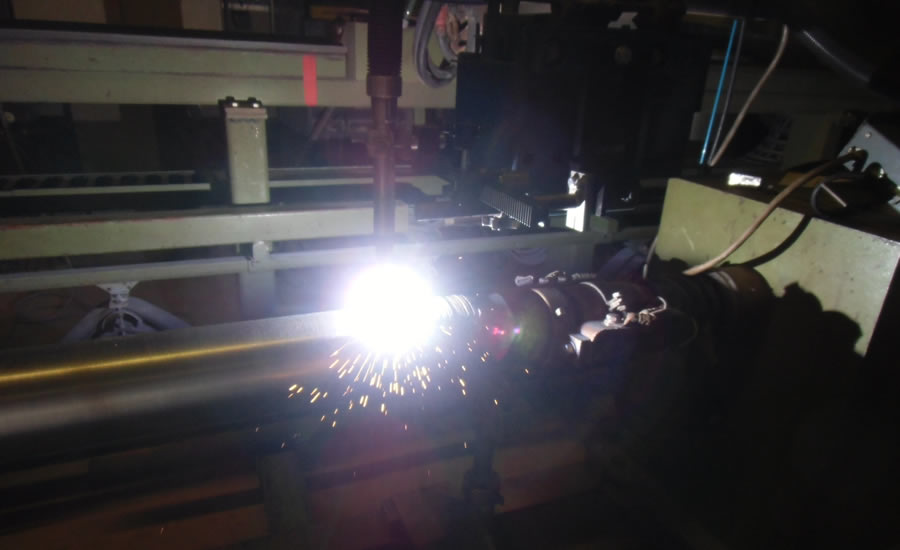

In the plasma powder buildup welding the surface of the work piece is melted with a plasma arc. The plasma is generated using a plasma gas (for example, Argon, Helium) through an electric arc between the cathode and anode.

The high-density plasma arc created in this procedure, serves as the heat source.

A metal powder is used as a coating material.

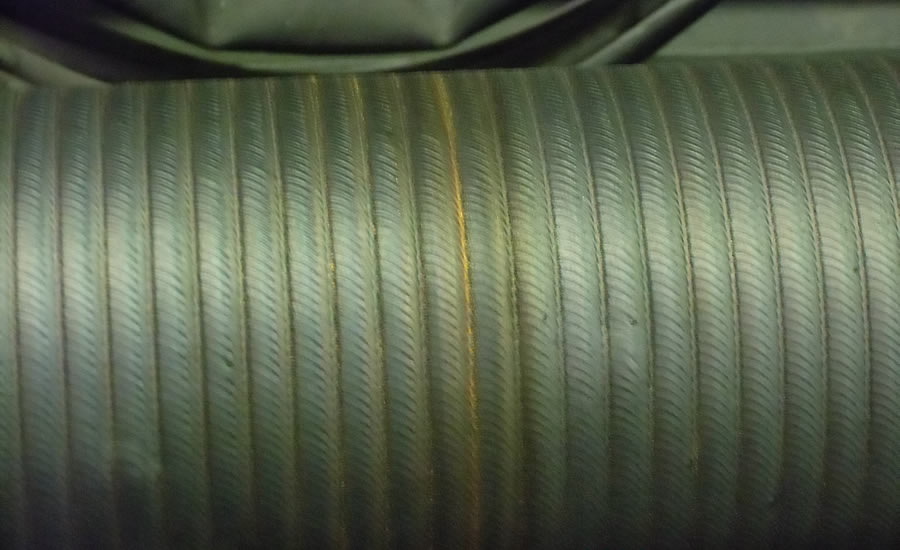

In this procedure the powder is heated in the plasma and applied respectively melted on to the work piece. This process for the application takes place in an entirely controlled atmosphere.

The advantages of this method

The PTA process has a minimal mixing of base and coating material (5-10%) and a small heat-affected zone, a high deposition rate with appropriate material and degrees of automation. This context creates a metallurgical connection between the work piece and the applied layer with relatively thin layer thickness.

Full details as also the selection of the coating materials (flux powder) can be discussed and made by inquiry.

For example: (cobalt-based, nickel-based or iron-based alloys).

For any further question regarding plasma powder buildup welding, please do not hesitate to contact us:

Telephone: +49 651 96770

Or send us your questions by using our contact form.

ADRESSE & KONTAKT

Comes Maschinen- und Apparatebau GmbH

Seiferstraße 16

54293 Trier-Ehrang

Telefon: +49 651 96770

Fax: +49 651 9677200

E-Mail: info@comes-trier.de

ÖFFNUNGSZEITEN

Montag bis Freitag

07:30 Uhr bis 12:00 Uhr

12:30 Uhr bis 16:15 Uhr

WARENANNAHME

Montag bis Freitag

07:30 Uhr bis 15:30 Uhr

SERVICE

NAVIGATION